Applying science and technology to safe tea production

|

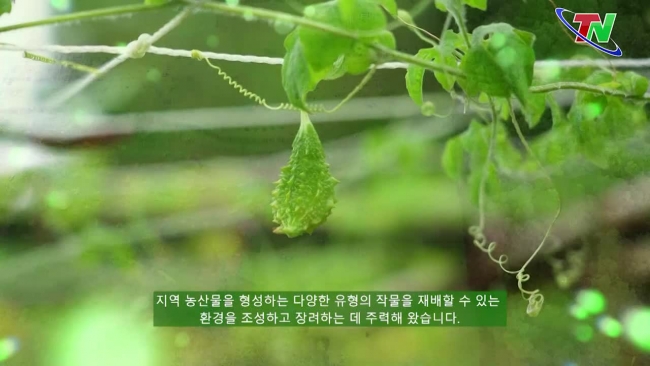

Phú Lương district currently has over 4,000 hectares of tea. From 2020 and before, many households in the district have approached and applied science and technology in tea production and processing, such as: Installing water-saving irrigation systems; applying organic microbial fertilizers; using biological plant protection products… However, the area of tea applying high technology in production is still limited.

Evidence of this is that the tea area certified to VietGAP standards only accounts for 6.8% (equivalent to 289ha) of the total area; the tea area equipped with water-saving irrigation systems has only reached 505ha (accounting for 12%); the tea area using organic microbial fertilizers accounts for about 10%...

Talking with us, Mrs. Nguyễn Thị Thu Trang, Head of the Department of Agriculture and Rural Development of Phú Lương district, said: From 2020 until now, people in the area have boldly invested in and applied science and technology in tea production and processing to improve product quality and value. Besides, from capital sources (provincial and district budgets; programs, projects…), we have coordinated with agencies and units to implement programs supporting equipment for tea processing for people such as: supporting 1,063 rolling machines, 57 stainless steel drying trays, 6 electric drying trays, 1 cold storage, 27 biogas dryers, nearly 200 tons of fertilizers and biological plant protection products; nearly 46,000 QR Code stamps for some tea cooperatives producing according to VietGAP standards… with a total cost of over 9 billion VND to give people more favorable conditions for production development.

As one of the establishments actively applying science and technology in tea production and processing, Mr. Hoàng Văn Tuấn, Director of Phú Đô Safe Tea Cooperative, said: In 2018, I researched and self-produced organic fertilizers from biochar, composting with manure and agricultural by-products to fertilize tea plants. I use chili, garlic, ginger, and forest leaves as pesticides on tea plants. With this method, the cooperative has produced and self-supplied over 90% of organic fertilizers for 20ha of tea. In addition, I also use biomass gasification stoves to process tea, creating fresh air and protecting the environment.

With the active application of science and technology in tea production and processing, to date, Phú Lương district has built 5 tea growing area codes, with the participation of over 500 households, with an area of over 87.5ha, concentrated in communes such as: Tức Tranh, Phú Đô, Vô Tranh...; nearly 873ha of commercial tea have been granted certificates of production according to VietGAP standards; 50% of the tea area is equipped with water-saving irrigation systems...

In the coming time, Phú Lương District People's Committee will continue to propagate and mobilize people to synchronize science and technology in all production and processing stages to improve product quality. Besides, it is to encourage people to synchronize science and technology in all production and processing stages to improve product quality; and allocate funds to support cooperatives and cooperative groups with equipment and machinery in tea production and processing...

Latest News

Dai Tu: Farmers' Association members contribute over 35.5 billion VND to the construction of new rural areas

The Youth Union of the University of Medicine and Pharmacy volunteers in Vu Chan Commune

Phu Binh Power Company: Spending nearly 70 million VND to thank customers

TYM - Thai Nguyen branch: A trusted friend of poor women

Other news

Encouraging members to actively participate in social activities

Promoting the tradition of Truong Son soldiers

Thai Nguyen: 100% of tested samples ensure food safety

Phu Binh: 2 more products recognized as 3-star OCOP

Protecting livestock in cold weather

Most read

IMPLEMENT THE PROJECT "IMPROVING THE EFFECTIVENESS OF EXTERNAL INFORMATION WORK OF OVERSEAS VIETNAM REPRESENTATIVE AGENCIES ABROAD TO 2030" IN THE PROVINCE

CREATING JOBS FOR ETHNIC MINORITY YOUTHS

PROMOTING IMPLEMENTATION OF RESCUE ACTIVITIES OF NETWORK INFORMATION SECURITY INCIDENTS